English

English

English

English

Views: 10 Author: Site Editor Publish Time: 2025-12-11 Origin: Site

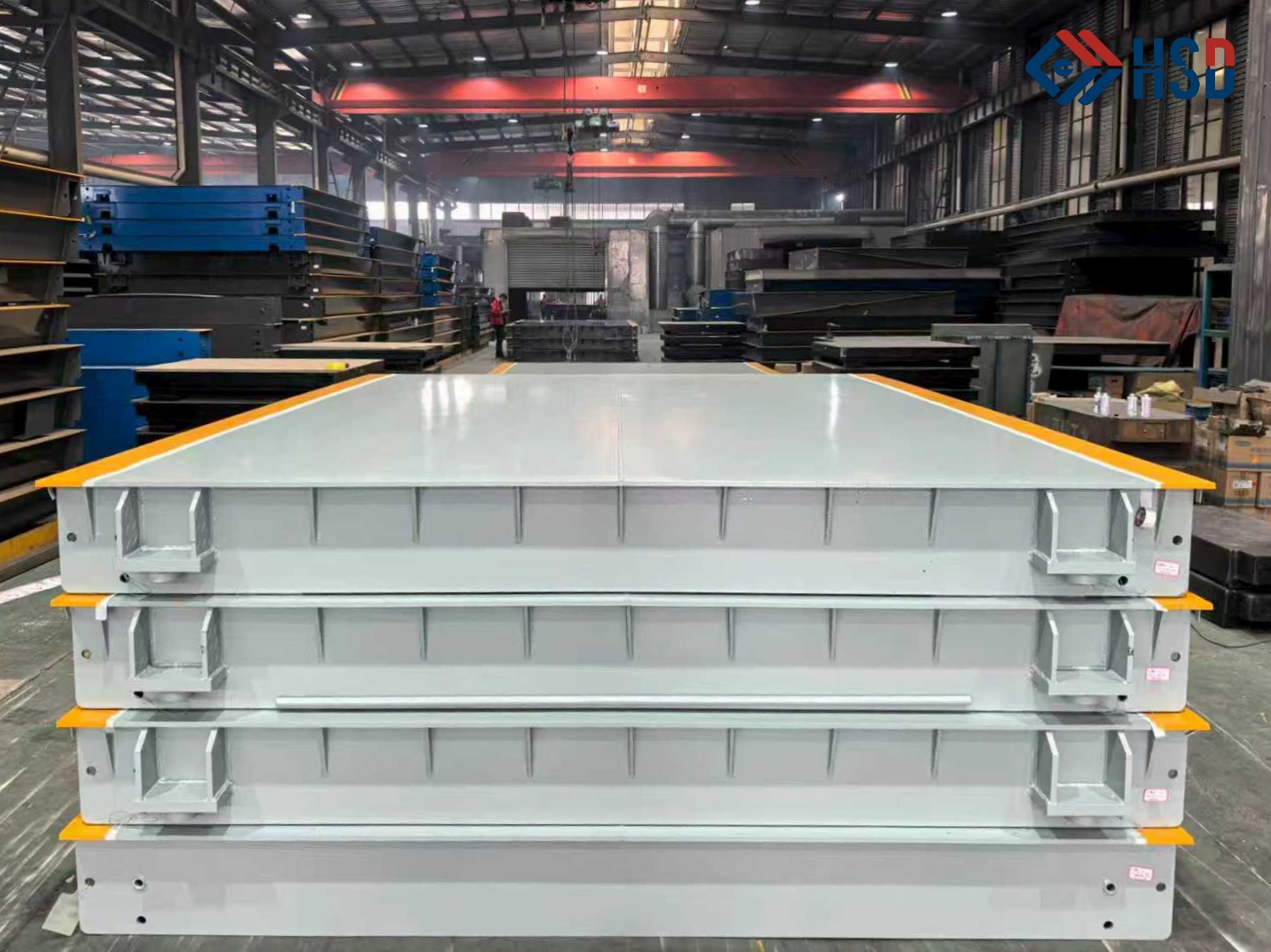

In industrial scenarios such as port freight, mine mining, and building materials processing, weighbridge is an indispensable basic equipment. Whether it is the load measurement of heavy trucks or the in-out warehouse accounting of bulk goods, truck scale plays a key role in accurate weighing. As an experienced weighbridge supplier, we will help you quickly understand the core value of weighbridge equipment today.

Origin and Technological Evolution of Weighbridge

he development of weighbridges began with mechanical structures in the early 20th century, which realized weighing by combining levers and weights. Low accuracy and cumbersome operation were the main problems at that time. With the breakthrough of electronic technology, traditional mechanical weighbridges have gradually been replaced by electronic weighbridges and become the current market mainstream. Today's lorry weighbridge has integrated sensor and intelligent chip technology, achieving a qualitative leap in weighing efficiency and data accuracy.

Core Working Principle: Achieve Accurate Weighing in Three Simple Steps

The working logic of modern weighbridge equipment is clear, and it mainly relies on the coordination of three core components: First, the truck drives onto the scale body (load-bearing mechanism), and the weight is evenly transmitted to the weighing sensor at the bottom; Second, the sensor converts the physical weight into an electrical signal and transmits it to the weighing display instrument; Finally, after the instrument processes the signal, it displays the weight data in real time, and some equipment can also complete data storage or printing simultaneously.

Main Types of Weighbridges and Their Applicable Scenarios

Standard Electronic Weighbridge: The most commonly used truck scale, with a load capacity of 30-200 tons, suitable for conventional freight weighing in logistics parks and factories.

Portable Weighbridge: Modular design, easy to move and install, suitable for temporary freight points or construction sites.

Unmanned Weighbridge: Integrating license plate recognition and automatic pole-lifting functions, no manual operation is required throughout the process, suitable for high-frequency weighing scenarios such as mines and ports.

Explosion-Proof Weighbridge: With explosion-proof certification, sensors and instruments are safely processed, specially designed for hazardous environments such as chemical industry and oil and gas.

Core Advantages of Modern Weighbridges

Compared with traditional equipment, today's weighbridge equipment has achieved multi-dimensional improvements in performance: High accuracy, the error of the core sensor can be controlled within ±0.02%, meeting the needs of trade settlement level; Strong durability, the scale body is made of anti-corrosion steel, which can adapt to harsh industrial environments such as high temperature, humidity and dust; High efficiency, the time for a single weighing is no more than 1 minute, and data can be automatically uploaded with the intelligent system; Easy management, weighing data can be connected to the enterprise ERP system to realize integrated management of in-out warehouse data.

Full Industry Coverage: Wide Application of Weighbridges

As a basic measuring equipment, the application of weighbridge has penetrated into the entire chain of industrial production: In the logistics industry, it is used for load verification of freight vehicles to avoid overloading risks; In the mining industry, it is used for loading measurement of ore and coal to accurately calculate production capacity; In the construction industry, it is used for weighing incoming building materials such as sand, gravel and cement to control project costs; In the manufacturing industry, it is used for weight verification of raw material storage and finished product delivery to ensure production compliance.

Future Trend: Intelligent Upgrade Direction of Weighbridges

With the integration of the Internet of Things and big data technology, weighbridges are developing in a more intelligent direction. In the future, truck scales will realize the whole process of digitalization, and weighing data will be synchronized to the cloud platform in real time to support cross-regional management of enterprises; AI visual recognition technology will further optimize the unmanned system and reduce the misjudgment rate; Predictive maintenance of equipment will become possible, and the operation status will be monitored through sensors to warn of faults in advance and reduce downtime losses.

Conclusion

From mechanical to intelligent, the development of weighbridges has always kept up with the pace of industrial upgrading. As a professional weighbridge supplier, we are committed to providing weighbridge equipment suitable for different scenarios, and helping enterprises improve efficiency and control costs with accurate and durable products. Whether you need a standard truck scale or a customized lorry weighbridge, you can contact us at any time.