English

English

English

English

Views: 3 Author: Site Editor Publish Time: 2025-08-28 Origin: Site

As essential industrial weighing equipment, floor scales require highly sophisticated manufacturing processes with strict precision standards. The production workflow encompasses multiple critical stages: design development, material selection, structural fabrication, welding techniques, surface treatment, sensor installation, electrical system integration, calibration testing, and final packaging and distribution. Each phase demands meticulous calculations and rigorous quality control to ensure products meet international standards (e.g., OIML, NTEP) while fulfilling client-specific requirements. Modern floor scale production extensively utilizes automation technologies and digital management systems, which not only enhance operational efficiency but also guarantee product consistency and reliability.

The production of weighbridges begins with detailed design and engineering planning. Engineers utilize computer-aided design (CAD) and computer-aided engineering (CAE) software for structural modeling and mechanical simulations, ensuring structural stability and accuracy under maximum loads. The design must comprehensively consider operational scenarios, such as the varying requirements for size, weighing capacity, and corrosion resistance in different environments like ports, mines, and logistics warehouses. Additionally, modular construction is incorporated to facilitate transportation and on-site installation. After completing all designs, material selection becomes the critical step. The main body of weighbridges typically uses high-strength alloy steels (such as Q345B or ASTM-standard steel), which exhibit excellent mechanical properties and fatigue resistance. Key load-bearing components may undergo additional reinforcement, while corrosion-resistant weighbridges in corrosive environments can employ stainless steel or hot-dip galvanized components.

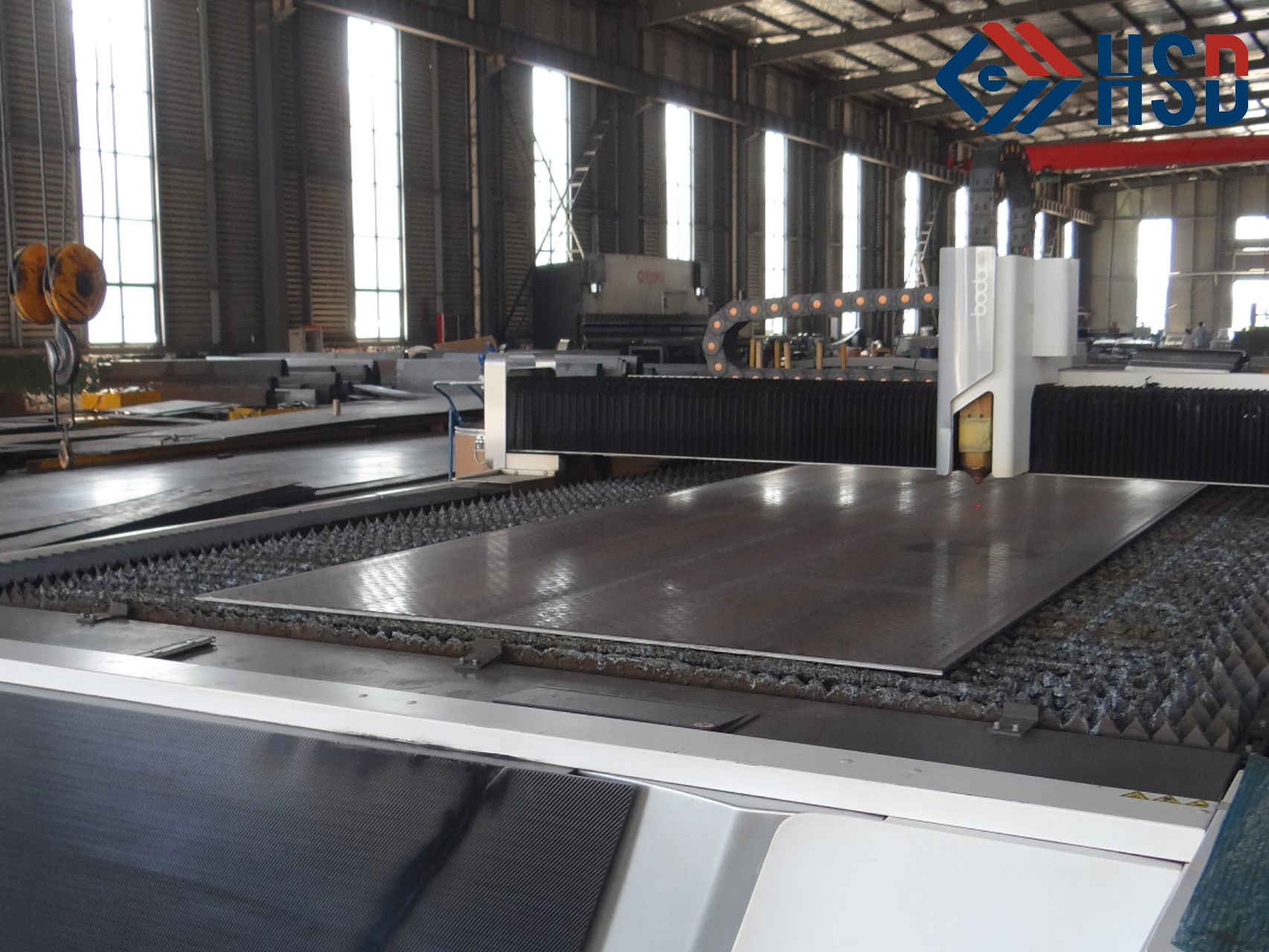

The manufacturing process involves three core stages: cutting, forming, and welding. CNC laser or plasma cutting machines are used to precisely cut steel plates into designed shapes and dimensions, ensuring millimeter-level precision control. Subsequently, large bending machines and hydraulic equipment are employed to cold-form the steel into beams, panels, and support structures for the weighbridge. As one of the most critical manufacturing steps, welding directly determines the structural strength and long-term safety of the weighbridge. Certified welders perform high-efficiency welding techniques such as submerged arc welding (SAW) and gas shielded arc welding (MAG), with strict non-destructive testing (including ultrasonic or X-ray inspection) conducted on critical welds to eliminate defects like incomplete penetration and cracks.

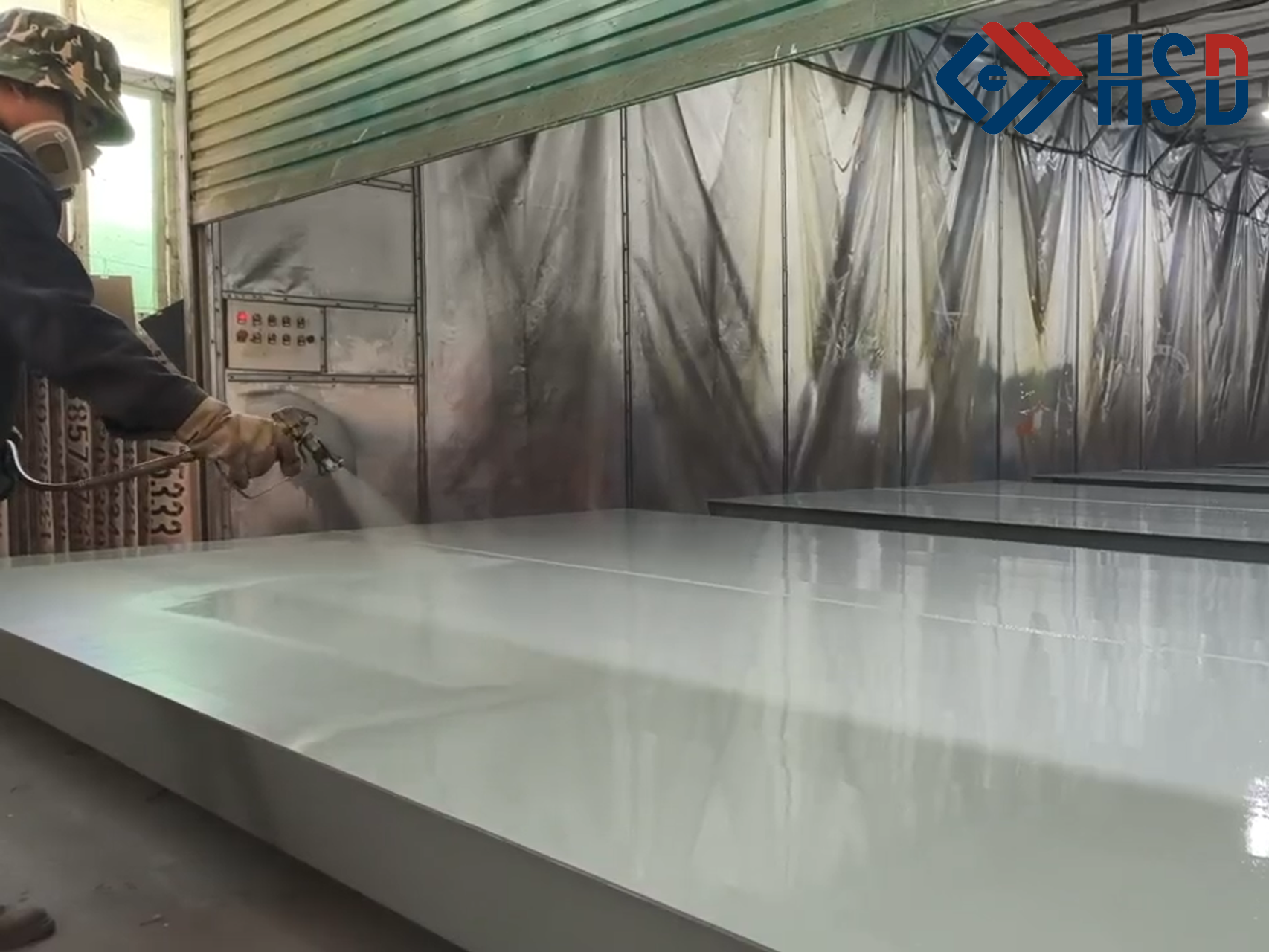

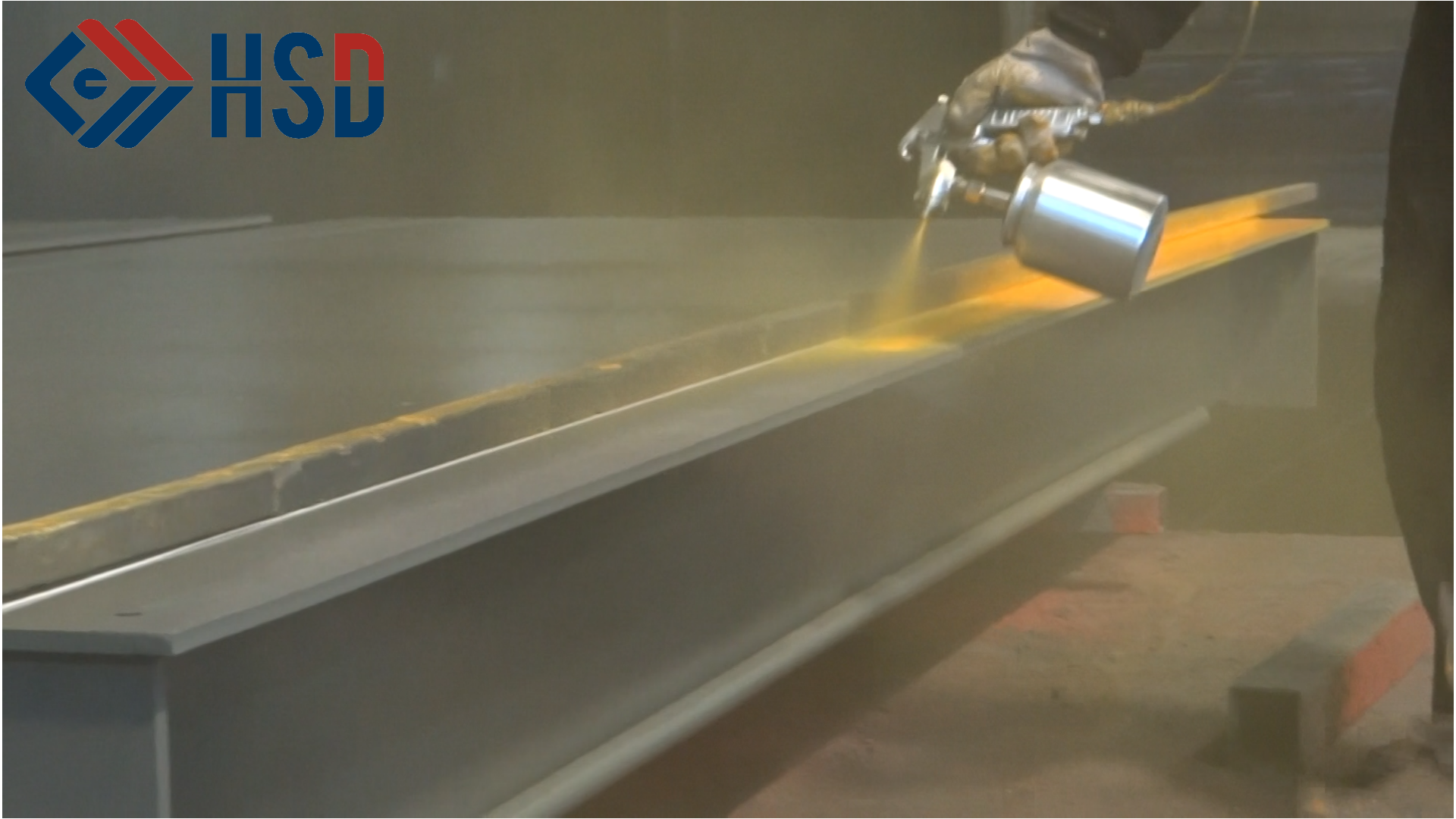

After structural welding is completed, the weighbridge enters the surface treatment phase. The process begins with sandblasting or shot blasting to thoroughly remove rust, oxide layers, and oil residues from the steel surface, enhancing coating adhesion. An epoxy zinc-rich primer is then applied using electrostatic spraying technology to ensure uniform coverage and effective corrosion resistance. The intermediate paint and polyurethane topcoat provide additional protection while delivering excellent weather resistance and wear durability. Custom colors can be tailored to client specifications. This comprehensive surface treatment not only improves environmental adaptability but also significantly extends the weighbridge's service life.

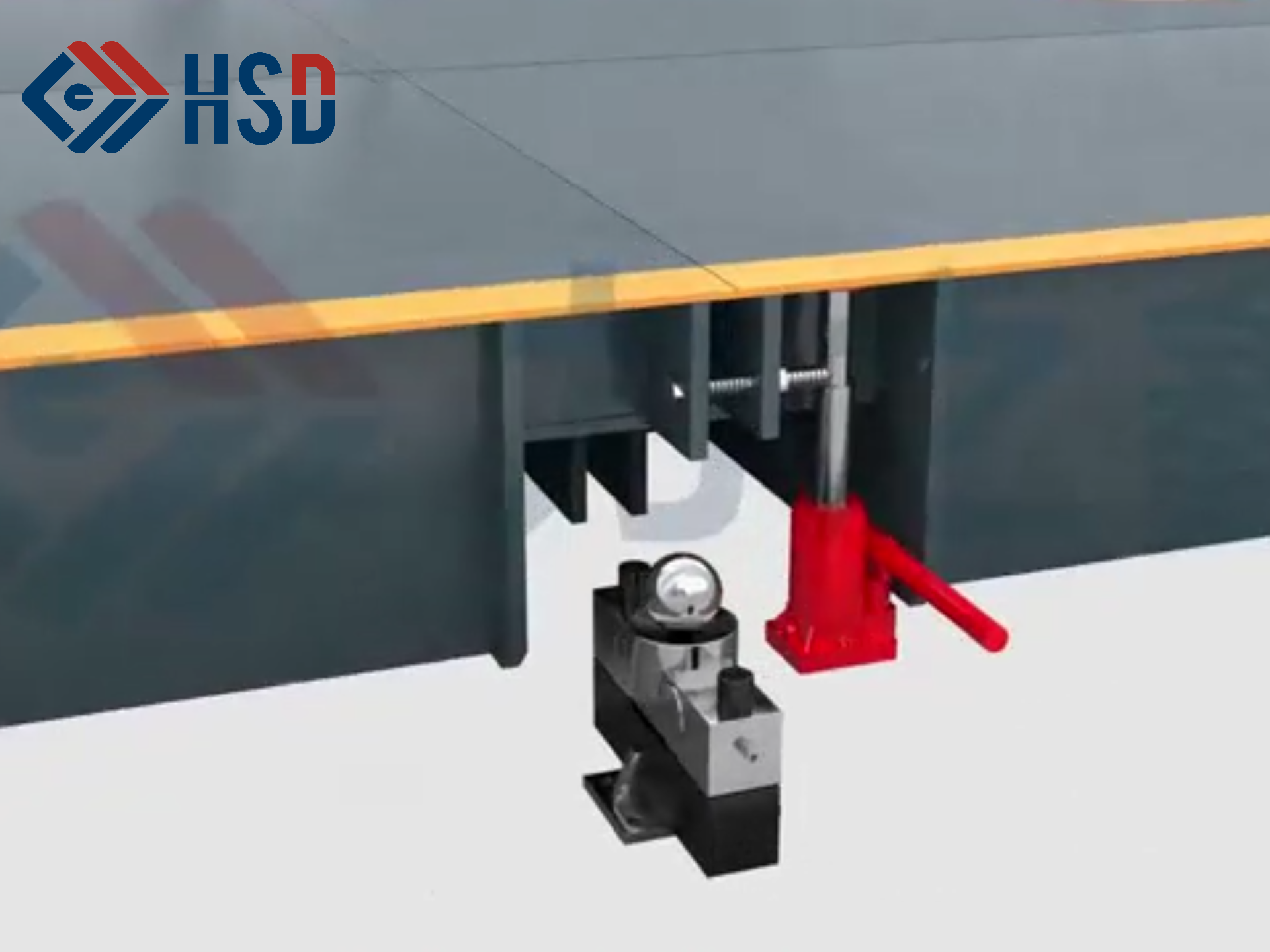

The subsequent phase involves installing the load cell and electrical system. High-precision sensors are mounted at predetermined support points and connected to junction boxes via signal cables. These sensors must meet stringent requirements including lightning protection, electromagnetic interference resistance, and moisture-proof sealing (IP68 rating). The electrical integration includes weighing displays, printers, data transmission modules (such as RS232 and Ethernet interfaces), along with software configurations. Initial system debugging is conducted to ensure accurate and stable signal transmission from the sensors.

After all components are installed, the weighbridge enters its final calibration and testing phase. Standard weights or calibration equipment are used to conduct multi-point loading tests, verifying its weighing accuracy, repeatability, and offset errors. Simultaneously, long-term stability tests and simulated environmental trials (such as temperature changes and humidity fluctuations) are performed to ensure reliable operation under various working conditions. Only weighbridges that pass all these rigorous tests will be approved for factory release.

Finally, the weighbridge is disassembled into modular components for packaging. These components undergo rust-proof treatment and are securely housed in wooden or metal crates to prevent damage during transportation. Each crate contains a detailed installation manual, calibration certificate, and after-sales service documentation. The entire production process is monitored through a quality management system (e.g., ISO 9001), ensuring every weighbridge product complies with design specifications and international standards. This guarantees clients access to durable, accurate, and reliable weighing solutions that deliver long-term reliability.