English

English

English

English

Views: 8 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

In the global fields of industrial logistics and trade settlement, electronic truck scales (weighbridges), as core measuring equipment, their accuracy and intelligence directly affect enterprise operational efficiency. With the in-depth penetration of the Internet of Things (IoT) technology, traditional truck scales have been fully upgraded to intelligent weighing systems, becoming an important support for enterprises' digital transformation. As a leading Chinese manufacturer deeply rooted in the truck scale industry, we will explain in detail the core components, working principle and upgraded advantages of modern electronic truck scales for global customers.

The working process of modern electronic truck scales has achieved a closed loop of "mechanical bearing - electronic sensing - intelligent processing - data interconnection", with significantly improved accuracy and efficiency compared to traditional equipment. The specific principle is as follows:

Gravity Transmission: When a loaded vehicle or goods are placed on the carrier platform, the gravity is evenly transmitted to each weighing sensor through the scale structure, triggering micro-deformation of the sensor's elastic body.

Signal Conversion: The strain gauge bridge built into the sensor loses balance due to elastic deformation, outputting a weak electrical signal proportional to the weight. After being amplified by the preamplifier, the signal is transmitted to the junction box for signal integration.

Data Processing: The integrated electrical signal is converted into a digital signal by the A/D converter. The instrument's microprocessor (CPU) performs error correction with intelligent algorithms and displays the weight data in real time. If equipped with an intelligent system, the data can simultaneously complete additional processing such as license plate matching and abnormal warning.

Interconnection Application: The processed weighing data can be uploaded to the enterprise management platform via wired or wireless means, supporting functions such as real-time query, statistical report generation, and historical data traceability. After configuring the cloud module, customers can remotely monitor the equipment operation status through a mobile APP.

Adhering to the core R&D concept of "Accuracy, Stability, Intelligence", HSD truck scales integrate international advanced technology and local manufacturing advantages, forming three major technical highlights:

High-Precision Sensing System: Equipped with OIML-certified high-precision digital sensors, adopting a stainless steel sealed structure with a temperature compensation range of -20℃ to 60℃, ensuring the weighing error is controlled within ±0.02% in extreme environments. The sensor and junction box form a dual signal verification mechanism, effectively resisting electromagnetic interference and avoiding data drift.

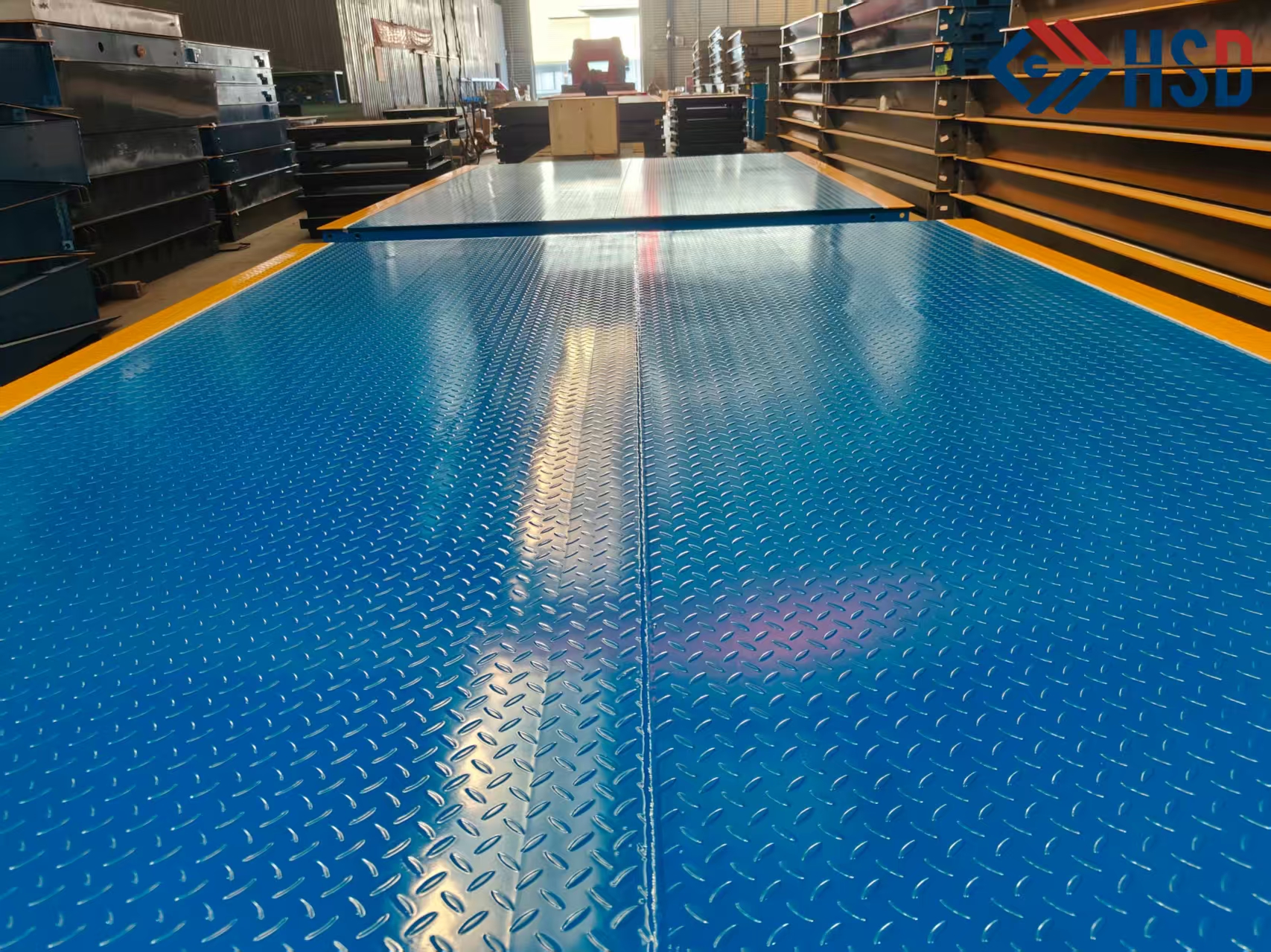

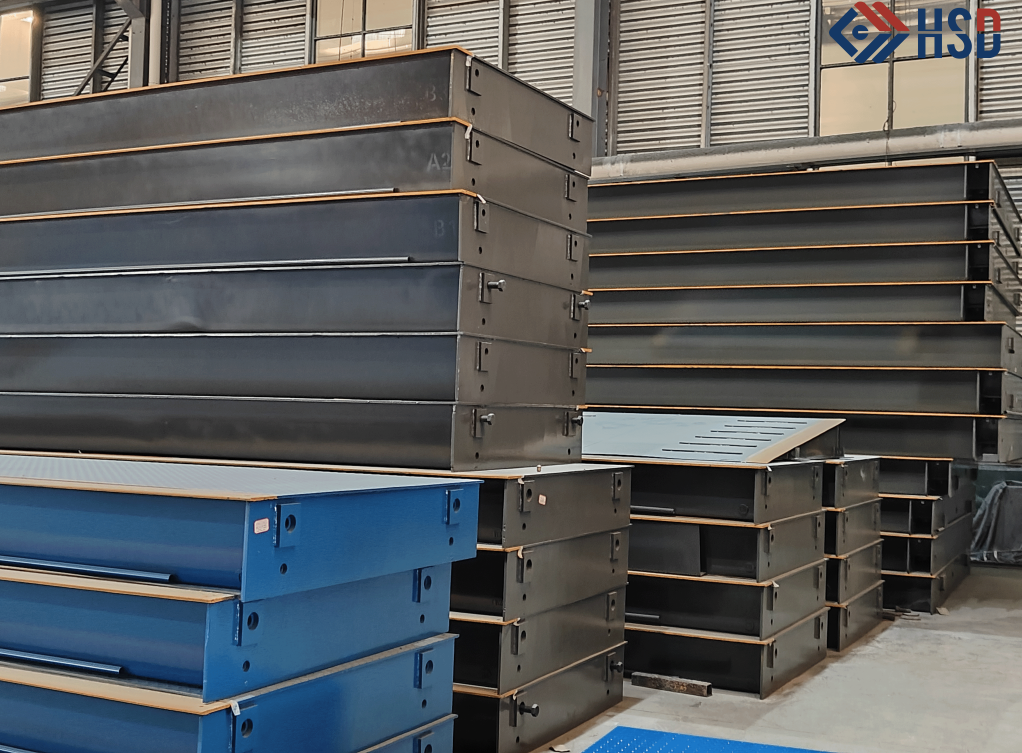

Durable Structural Design: Steel structure truck scales adopt Q235 high-strength steel, undergoing sandblasting derusting and double anti-corrosion treatment of galvanizing + spray coating, with a service life of more than 10 years. Specialized truck scales for specific industries are additionally equipped with anti-crushing edge protection and drainage systems, solving the harsh usage problems in scenarios such as mines and chemical industry.

Intelligent Interconnection Function: The unattended series of truck scales integrate modules such as automatic license plate recognition, infrared anti-cheating, and video surveillance. Weighing data can be synchronized to the cloud management system in real time, supporting remote query and statistical analysis via computers and mobile APPs. The instrument supports Chinese-English bilingual switching and is equipped with RS232/485 interfaces, enabling seamless connection to enterprise ERP and WMS systems, and realizing efficient collaboration between weighing and supply chain management

As a truck scale manufacturer deeply engaged in the foreign trade market, HSD has established a full-chain service system covering "R&D - Production - Transportation - After-sales", addressing the worries of international customers:

Compliance Guarantee: Products have passed international certifications such as CE, OIML, and ISO9001, complying with the metrological regulations and safety standards of regions including the EU, Southeast Asia, and Africa, ensuring smooth passage of local customs inspection and acceptance.

Customization Support: Customize shallow foundation/pitless installation solutions according to the customer's installation environment (such as foundation conditions and climate characteristics), with supporting multilingual foundation drawings and installation guides to reduce construction difficulty.

Global Logistics and After-sales: Cooperate with professional international freight forwarders, supporting multiple transportation methods such as sea freight and air freight to ensure the equipment is delivered intact.